12 INNOVATIVE BUILDING MATERIALS OF TODAY

The innovative building materials of today are those which were not thought of until now, but has the capacity to change the way buildings are conceived, designed and built. It is innovative as it affects the size, utility, flexibility, strength, sustainability etc. of the built form. Cement was once an innovative building material and it revolutionized everything about the built forms. Here are listed 12 of the most innovative building materials which is awaiting widespread commercial usage.

1. SELF-HEALING CONCRETE

Scientist have been experimenting on self-healing concrete for the last 2 decades and have developed few types. It imitates the automatic healing of body wounds by the secretion of some kind of material. Three types listed here:

• Sodium Silicate-Based Self-healing Concrete developed in University of Rhode Island utilizes micro-encapsulated sodium silicate healing agent. As cracks form in the concrete, these capsules rupture and release the sodium silicate. The healing agent reacts with the calcium hydroxide within the concrete, forming a calcium-silica-hydrate gel that repairs the crack and hardens in about a week.

• Bacteria-Based Self-Healing Concrete invented by Henk Jonkers, a microbiologist and professor at Delft University of Technology in the Netherlands using bacteria Bacillus for the job. The bacteria thrive in the high-alkaline conditions of concrete and produces spores that can live up to four years without any food or oxygen. Calcium lactate is also added to the limestone concrete mixture in order to feed the bacillus so that they can produce limestone to repair cracks in the concrete.

• Fungus-Based Self-Healing Concrete was created taking inspiration from our own bodily functions, scientists at Rutgers University and Binghamton University created a fungus-based self-healing concrete. Their concrete relies on spores from the Trichoderma Reesei fungus. These spores remain dormant until the first cracks begin to emerge, at which point they begin to fill in these areas.

Theses self-healing concretes can save millions of tax payers money spent every year in repair of public buildings, roads, bridges etc.

2. WASTE MATERIAL

The most under-rated building material which is entering mainstream in various ways is waste material and is probably the most environmentally sustainable. Recycled materials like scrap metal, cardboard, plastic bottles can be used to create new buildings with smaller carbon footprints.

One of the waste material is cigarette butts. This amounts to about 1.2 million tons of waste every year. Scientists at RMIT University in Australia have found a way to utilize the cigarette butts by infusing them into bricks thus, making a durable and efficient building materials in the process.

Recycled cardboard, for example, is being used to create high-quality cellulose insulation that outperforms insulation made with traditional processes. Polymers such as rubbers, elastomers, thermosets and mixed plastic waste are comfortably labelled as “unrecyclable” by the recycling sector but they can be used in manufacturing building material too.

A company in Arizona has managed to recycle denim and recycled carpet fibres into insulation. Ice Stone is tile used for counter tops etc, mimics the look of terrazzo, a composite traditionally made with small pieces of marble or granite. Instead of mined stone, Ice Stone uses post-consumer glass from industrial recycling facilities. The resulting surface is both heat and scratch-resistant. Interlocking tiles can be manufactured from 100 percent post-consumer waste tires. The resulting tiles are lightweight, slip-resistant, puncture-resistant. Similarly there are many waste un-recyclable and recyclable materials that are being used as building materials.

3. STRAND RODS – CABKOMA

his product was developed and implemented in Ishikawa, Japan, an area with high seismic activity. This was used on existing structures for the purpose of adding additional seismic reinforcement.

The CABKOMA strand rod is made of a carbon fibre composite. Thin, oriented carbon fibre strands are used for the interlining. They are covered by an outer layer composed of synthetic and inorganic fibres intended to protect against weathering of the carbon fibres. The combination is then impregnated with thermoplastic resin.

It was developed by the Komatsu Seiten Fabric Laboratory in Ishikawa, Japan. It’s first application was designed by Kengo Kuma for use on the exterior of Komatsu Seiten’s head office building. The three-story structure is currently used as a workspace, exhibition, and research facility.

The workability of strand rod is due to the thermoplastic impregnation and the ability to recycle the material are highly advantageous attributes. This composite has also been used to make lighter automobiles and aircrafts, reducing their fuel consumption and making their overall design more efficient.

4. TRANSPARENT ALUMINIUM

However strange the term transparent Aluminium may sound, it is a revolutionary ceramic alloy created by fusing nitrogen, oxygen and aluminium in precise measures.

Transparent Aluminium is three times stronger than steel, four times harder than fused silica glass, 85 percent harder than sapphire and, as the name suggests, optically transparent.

The material is corrosion, radiation and oxidation-resistant and could be used to produce windows and domes for undersea and deep-space vehicles, lenses for high-impact cameras and other types of safety glass. You could even clad skyscrapers with it. Other potential applications include insulators and heat radiation plates, translucent ceramics, metal matrix composites, high temperature materials and thermally conductive fillers. The commercial version of transparent aluminium is ALON. It is already being used by the military for making armoured windows and optical lenses which can also resist powerful bullets.

5. GRAPHENE

Graphene was discovered approximately 12 years ago and is set to change almost every industry in the world including construction, although it is still waiting for large-scale adoption. Graphene is an allotrope of carbon consisting of a single layer of atoms arranged in a two-dimensional honeycomb lattice and is up to 200 times stronger than steel, yet it is ultra-lightweight and the thinnest material known to man. It even acts as a barrier to gases.

Graphene is resistant to both friction and weather conditions. One of the great advantages is that graphene, being composed of carbon, is an organic material which means that it is not only greener but also healthier.

Even though the usage has limitless possibilities, the mass production is limited by its high costs. Six uses in construction and Real-estate Industry can be listed as below:

- Long-lasting LEDs

- Impermeable paint

- Corrosion-proof steel

- Interactive panels

- Spray-on solar panels

- Self-cleaning concrete

When Graphene shards are incorporated into concrete, it results in concrete blocks which is twice as strong and four times more water-resistant than normal concrete.

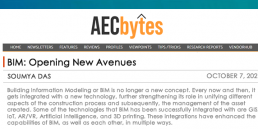

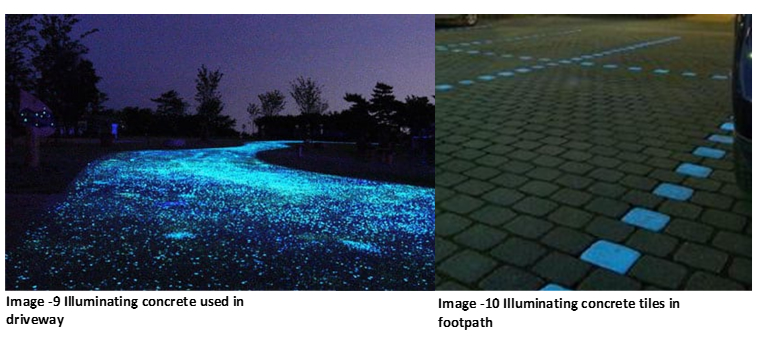

6. ILLUMINATING/GLOWING CONCRETE

This was developed in Mexico’s Michoacan’s University of San Nicolas Hidalgo (MSNH) is a new kind of glow-in-the-dark, solar powered cement that is able to absorb solar energy and then radiate it back into the night sky in the form of light. From footpaths to highways, it could have some very interesting applications.

A drawback of most glow-in-the-dark materials is that they are composed of plastics and have a short lifespan of around 3 years at most because they decay under exposure to UV light. José Rubio, the innovator behind the material however says that this new kind of cement can last up to 100 years.

German-based manufacturer Kann has developed luminous concrete pavers called NightTec Leuchtsteine. Phosphorescent crystals embedded in the concrete surface capture diurnal energy and emit light every evening for about ten hours. Although the pavers appear white in sunlight, their nocturnal glow is either green or blue depending on the selected material.

7. MARTIAN CONCRETE

When we finally start colonizing other planets like Mars, we’re going to need concrete to make buildings and infrastructure. But concrete needs water, and Mars doesn’t have any. Scientists have found a solution. Sulfur, when heated up to 240 degrees Celsius it liquefies, that can be used along with aggregate which is abundantly available in Mars.

Mars has tons of Sulfur, maybe as much as 17% of the entire planet. That’s why Northwestern’s researchers think that Sulfur is going to be the key to the Red Planet’s big construction. By using simulated Martian soil consisting of silicon dioxide, Aluminum oxide, Iron oxide, Titanium dioxide, and mixing this aggregate 50/50 with molten Sulfur, they were able to make blocks of quasi-Martian concrete. And it’s two-and-a-half times as stronger than most commonly used concrete on Earth.

There’s another advantage of Martian concrete over Earth concrete, too. On Earth, concrete production is the third biggest contributor of CO2 emissions, largely because of the huge volumes of concrete used to build. But on Mars, the concrete could literally just be re-heated until the Sulfur melts, and the entire concrete block becomes malleable again. That means any Martian concrete will be almost be infinitely reusable, without taking the same toll on Mars as it is taking on Earth.

8. BREATHING BRICKS

Indoor air quality (IAQ) is becoming a more important concern for commercial real estate as we gain a better understanding of how built environments affects the health of those who live and work in them. Current systems require active energy use to filter the air and this approach emits more carbon and other pollutants into the air over the long term.

Researchers have invented a passive system that makes use of the bricks on the outside of the building to filter out the heavier particles in the air as it enters the space. The concrete bricks funnel air into an internal cyclone filtration section that separates heavy elements and drops them down into a hopper at the base of the wall. Clean air is then pulled into the building, either mechanically or passively, and maintenance can simply remove and empty the hopper on a periodic basis. One third of fine particulate matter can be expected to be removed by this process.

Best of all, these bricks can be added to an existing structure, meaning they can begin to take effect immediately, rather than waiting to be implemented only on newer buildings.

9. LIQUID GRANITE

Liquid Granite is a self-contained, pre-mixed cement, blended with specially selected aggregates. It is fire resistant to high temperatures and is made largely from recycled material, and is as versatile as concrete. Liquid Granite is lightweight and has the same load-bearing capacity as cement.

Liquid Granite being made up of between 30 and 70 percent recycled material, can greatly reduce carbon footprint as compared to cement. Around 2bn tonnes of cement is used every year and for each tonne produced, 0.4 tonnes of carbon dioxide gets released in the process. The cement industry is responsible for 5% of the world’s carbon emissions – more than the entire aviation industry.

Liquid Granite was developed by Scientists at the Sheffield Hallam University in England and they claim that liquid Granite has the capacity to completely replace cement.

Liquid Granite is an amazing floor repair material that sets in minutes and adheres to a wide range of building materials including concrete, metal and asphalt.

10. HYDRO-CERAMIC BRICKS

The thermodynamics of a building can be tackled passively with a class of material called ‘hydrogel’. The term ‘hydrogel’ refers to a class of substances that absorbs and retains 500 times their weight in water. Chemically they can be insoluble polymers of hydroxyethyl acrylate, acrylamide, polyethylene oxide, and others.

As a cooling aid they work by exposing the absorbed water to a large surface area. Since the heat of vaporization of water is about 0.6 kilocalories per gram, a cooling effect occurs.

Hydro-ceramic works as an evaporative cooling device which reduces temperature, increases humidity and is capable of lowering down the temperature of the indoor environment by about 5 to 6 degree. It’s passive embedded intelligence makes its performance directly proportional to the heat in the outdoor environment i.e. it cools more when it is more hot and doesn’t cool when no evaporation is occurring. It can help save up to 28% of overall electricity consumption caused by the traditional air-conditioning and can be used as an low-cost alternative building technology as both clay and hydrogel are inexpensive.

11. TRANSLUCENT CONCRETE

The concrete structure is known more for its stability than its great lighting but translucent concrete changes this.

Translucent concrete is manufactured by using glass fibre optical strands, which create a solid but sheer block. Translucent concrete is made by combining two major materials; fine concrete (with cement and aggregates like sand) and optical fibres.

LitraCon, known as transparent concrete can be used in walls and other places. Since, the optical fibres make up only 4 percent of the mixture this material, translucent concrete blocks have the ability to act as load-bearing walls. Translucent concrete allows natural daylight to penetrate deep into building interiors that might otherwise lack any light at all. Additionally, when used with artificial lighting, translucent concrete can facilitate creative designs for retail and residential properties.

12. BENDABLE CONCRETE

A flexible or bendable concrete is an engineered cementitious composite (ECC) that exhibits the property of ductile material unlike the brittle nature of conventional concrete.

Bendable concrete is filled with small fibres, generally polymer-derived, organized into a microstructure that helps give the material increased ductility in comparison to traditional concrete, which is prone to cracking and failure under strain and long-term use.

Flexible concrete is different than traditional concrete in composition, it has polyvinyl alcohol fibres and very fine silica sand instead of course aggregate. Other fibres such as silica fibres, glass fibres, steel fibres, and asbestos fibres can be used. These micro-fibres give the new concrete its flexibility. The flexible or bendable concrete was developed by Prof. Victor Li at the University of Michigan.

Conclusion

Besides the innovative building materials mentioned here, there are many more materials that are as amazing. These materials if they stand the test of time will enter mainstream. Cement which was once an innovative building material is now the life of all constructions. Researchers every other day are coming up with new materials that is breaking new barriers. Who would have thought few years earlier that humans would plan to colonise Mars and that scientists would be ready with a solution to build houses even there.

Note: All information published here are collected from various websites hosted publicly. However, the conclusion is solely my own view and not of the organizations I am associated with.